FUNCTIONAL WATERS

Some commercial water ionizers allow you to add sodium chloride (NaCl) to the source water, which increases the conductivity of the water resulting in functional waters called strong acidic water (produced at the anode) and strong alkaline water (produced at the cathode).1

PROPERTIES OF STRONG ALKALINE WATER

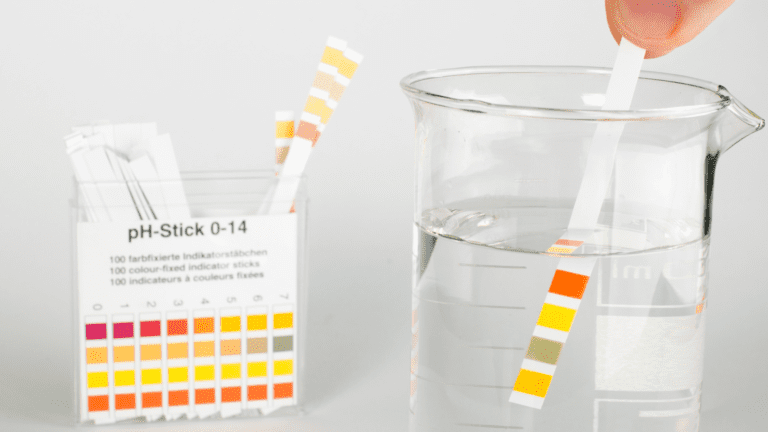

Electrolyzed alkaline water is produced via electrolysis of a NaCl solution at the cathode side.2 The resultant product is a solution of sodium hydroxide (NaOH) with a pH of 11-13.8 and a negative ORP of -750 to -900 mV3 due to the dissolved hydrogen gas. It may also contain small amounts of platinum-nano particles4 as the NaCl increases the propensity of degrading the electrode plates.

USES AND BENEFITS

This cathodic water is considered a functional water because it is used for cleansing,5 rinsing,6 disinfecting,7 lipid extraction,8 etc.9 It can readily saponify oils,10 making it a useful washing agent for greasy or oily areas.11-12 This also gives it the ability to reduce the pesticides on produce13-14 by soaking the vegetables in this water for 10-30 minutes.

It is important to note that using this water on produce generally alters the color of the water. Some have incorrectly claimed that the color is all the pesticides. The fact is that the color is due to the organic pigments of the food itself—because of the high pH of the water (see pictures/description below). Indeed, the same color change occurs even with pesticide free produce.

The above pictures clearly illustrate this point. In both pictures, the left cup is bottled water at an initial pH of 6.2 where tomatoes were soaked for the same amount of time as another batch of tomatoes, which soaked in the strong alkaline water (10 min). After soaking, the tomatoes were removed and the pH of the bottled water was increased to 11.2 by adding a simple alkaline chemical (i.e. ammonia). It is seen that the color is about the same, which indicates that the reason for the color change is simply because like with the tea demo, the color pigments act as “natural” pH indicators. This is further underscored by the same picture on the right, but where the pH of the strong alkaline water was decreased by adding acid (i.e. white vinegar) to a pH of 6.2. It is seen that the water went colorless because of the natural pH indictor properties of the tomato skin.

MIXING WITH OIL

Some have claimed that the reason this water can mix with oil is because it has a lower surface tension, or microclustering of the water molecules. However, both of these ideas are false and are pseudoscientific. Actually, the surface tension increases as pH and/or NaCl concentration increases,15 and microclustering is an abandoned myth16 with no credible scientific backing.17

Others have termed that the water mixing with the oil as emulsification; however, the water lacks a surfactant thus making this illogical. The mixing is that of saponification, which is a common process of making soap. The hydroxides hydrolyze the triglycerides to form carboxylates. This newly formed soap now has surfactant activity, which acts to emulsify the remaining oil.

It is observed that the ability of this water to saponify fats increases when stored for a day. A possible explanation for this is that as the water sits calcium salts (e.g. carbonates) form and drop out of the solution. This is important because calcium blocks micelle formation, which is important for final saponification/emulsification of the oil.

Because this water can mix with oil, another false claim has been perpetuated, which is that drinking this water or the mildly alkaline water can remove excess fat and cholesterol from inside of the body.18 This is absolutely false and is yet another reason why many ridicule the concept of ionized water. It is the high alkaline pH (?11.5) that is responsible for the mixing ability. The stomach acid would neutralize the alkaline water; furthermore, a blood pH high enough to mix with fats would be instantly fatal.